Features

Opinion

Tech

The Progress of Nanography

April 28, 2015 By Martin Habekost

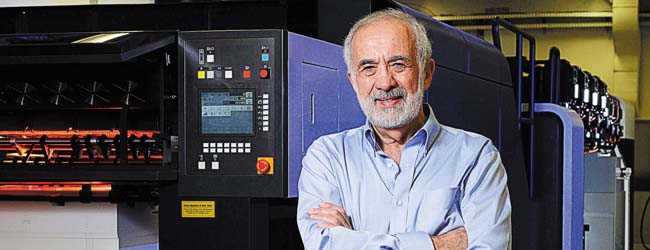

Printing pioneer Benny Landa founded Landa Digital in 2002 and unvieled its first innovative presses in 2012.

Printing pioneer Benny Landa founded Landa Digital in 2002 and unvieled its first innovative presses in 2012. With drupa 2016 a year away, I began thinking about the last time the giant German tradeshow in Düsseldorf took place in 2012 and the crowds at Landa Digital Printing’s exhibition space. Mostly, I remember the blue-and-black futuristic design of Landa’s new Nanographic Printing Presses, including the unique control panel mounted to the side of each press like a giant iPhone. I wondered aloud, “Shouldn’t there be a few presses already installed in print shops by this time?”

Providing as much function as form, the control screen GUI appeared to be well designed to meet the needs of a busy operator. There was even a digital microscope that came with each press, which I was immediately impressed with because it allows both operators and customers to look at the details of a printed sheet. Over the first days of the 14-day trade show, heavy iron manufacturers like Heidelberg, manroland and Komori joined Landa’s marketing buzz by announcing Nanographic technology partnerships, albeit a little vague.

Benny Landa, who founded the company in 2002, told drupa 2012 visitors the Nanographic presses could reach first adopters by the end of 2013 at the earliest, with initial machines hitting the market during the first months of 2014. I thought to myself: Let’s see if he can keep this deadline.

Nanography nutshell

The year 2013 came and went without any Landa Digital presses going into potential customers, although there may have well been quiet alpha testing going on inside an eager print shop. In March 2013, I attended the annual TAGA conference in Portland, Oregon, where Gilad Tzori, VP of Product Strategy of Landa Digital Printing gave the event’s third keynote presentation.

Tzori provided conference attendees, who primarily serve on the technical side of printing, an overview of how Landa Nanography works and differs from existing printing presses. Emphasis was put on Landa’s jetting of water-based inks which do not soak the paper, so the sheet does not come out wavy at the end of the press run.

Many people will have experienced this water-soaking problem when they print a sheet of paper with heavy coverage on their home or office inkjet printer. Tzori explained how the Nanographic printing process first inkjets the image onto a heated transfer belt, and secondly how the ink turns into a semi-solid type material on the transfer belt, which is then transferred onto the paper. Unique properties of Landa’s belt, explained Tzori, ensures a 100 percent transfer of the image onto the paper.

He then showed images of a printed dot produced with Nanography and compared it to the same magenta dot printed with different technologies currently on the market. The superior quality of the Nanographic process, in regards to the roundness and sharpness of the printed dot, was then described in Tzori’s marketing presentation. A clear advantage of Nanography indicates the process allows for printing on almost any substrate.

Nano pigments deliver a broader colour gamut than standard offset inks. The Landa black has L*a*b*-values of 5.4, 0.7 and 0.05 compared to the ISO standard of 16, -0.1, 0.1. The ink film is 500-nano-meters thick, which is a lot less than that of any other conventional printing process. The printed density for coated and uncoated paper is the same, since the ink does not sink into the uncoated paper but rather sits on top of the paper. De-inkability studies, explained Tzori, have also shown good results. De-inkability is a significant problem with regular inkjet printed sheets.

Nanography niche

After describing the technical architecture of Nanography, Tzori explained where Landa Digital sees its market niche and how it plans to bridge a gap between short-run digital and longer-run offset jobs. This includes targeting offset sheetfed work with a 40-inch or B1-format press model. Tzori stressed that Landa is not reinventing existing machine technology like paper feeding and delivery, which is why the company is working with traditional press makers, most notably Komori.

A key question to come from the conference crowd that day asked about the future availability of these new Nanographic printing presses. A careful answer was given, which I interrupted to mean it would be at the beginning of 2014, while the company’s main challenge was to achieve the desired print quality at the necessary resolution.

Year 2014 came and went and, without hearing much more from Landa in terms of press installations, I naturally started wondering if the past two years of Nanographic marketing had been all smoke and mirrors? In February of 2014, Landa Digital and EFI announced a strategic alliance and in June 2014 Altana invested €100 million into Landa Digital, which had also received a number of press down payments from printers wanting to be first in line. It is my guess that Altana will manufacture the Landa inks and EFI will deliver the digital front-end to the presses.

On December 9, 2014, Landa Digital made a public statement about its technology development, including its intent to focus on the 40-inch folding-carton market with its S10 press. The press has undergone some radical design changes, including the addition of a coating unit. The operator’s side-mounted touchscreen, as it was seen at drupa 2012, had to be moved to the delivery end – transforming its look more toward a traditional press design. The weight of the press has increased also from 10 tons to 30 tons.

Landa Digital explained the S10 operator now has a more ergonomic workplace showing all the required information for running jobs. Personally, I like the video feeds from inside the press to the operator cockpit. The press operator can see if any sheets have been dropped or if they are causing a jam. The presses also have an inline inspection unit from Advanced Vision Technology.

Within its online marketing material, Landa Digital writes: “The quality control solution will combine innovative nozzle performance and colour control techniques to maintain print quality and increase press productivity. The quality control system will also control colour-to-colour registration, image placement and front-to-back registration.” The print resolution of the S10 press is now at 1,200 dpi and the press also makes it possible to print on both sides of the carton sheet before entering the coating unit.

Nanography 2015

In early 2015, I spoke with Tzori on the phone to discuss recent developments at Landa Digital Printing. He indicated the first presses are scheduled to be commercially available in the second half of 2015. Beta machine are currently set up at Landa’s facilities in Israel, where potential customers can see the presses in action.

During our phone conversation, Tzori also discussed what kind of drying technology is installed between the coating unit and the delivery end of the press. Depending on what kind of coating the customer wants to use, there will be IR drying lamps installed for water-based coatings and UV-curing lamps for UV coatings. The UV-curing technology can either be UV-mercury vapour lamps or UV-LED.

Tzori points out that the IR or UV technology is only necessary for the coatings that are applied to the printed sheets. The sheets printed with the Nanography ink come dry out of the press.

Thinking ahead to drupa 2016, which surely will be another important exhibition for Landa Digital technology, I asked Tzori what is to come with regard to the company’s web-fed printing machines. The first web-fed printing machine will be geared towards the flexible packaging market.

Landa Digital expects this to make a huge impact on the flexible packaging sector, especially with many of the other digital press manufacturers also developing printing solutions for the short-run flexible packaging market. I have every intention of attending drupa 2016 for a firsthand view of Landa’s developments and I expect they will be as interesting as Nanography’s unveiling three years ago.

Print this page