Features

Colour Control

Premedia

Expanded Gamut Printing

April 19, 2016 By Abhay Sharma

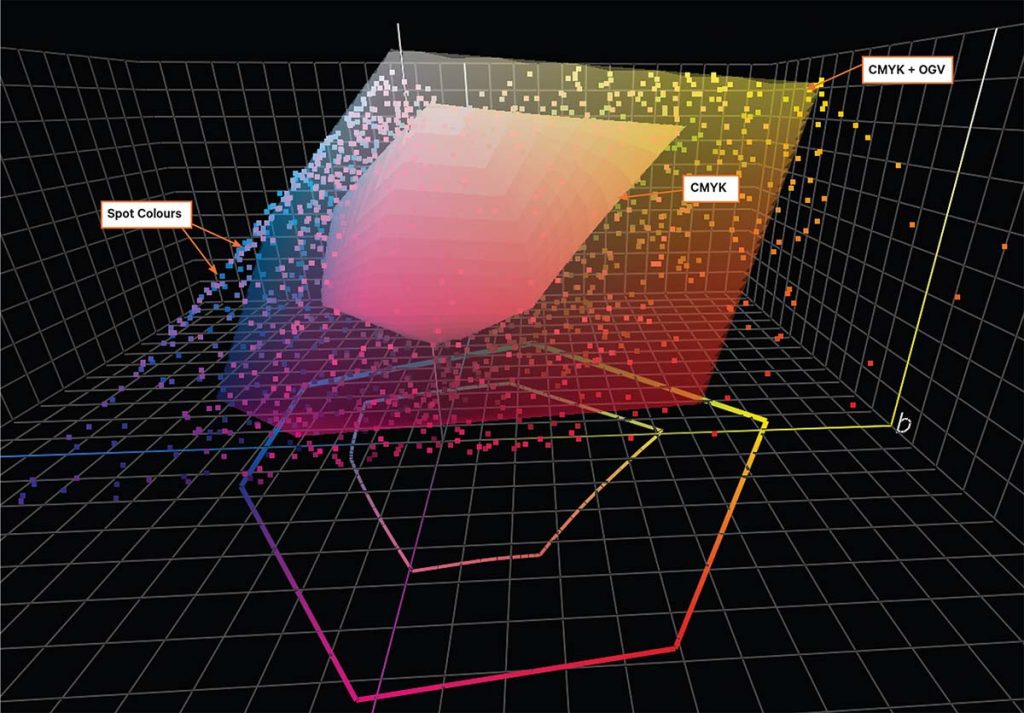

The small squares generated in this colour gamut by the author are the 1,729 spot colours of the new PANTONE+ Extended Gamut swatch book. A CMYK+OGV and a CMYK gamut are simulated by the larger and smaller volumes in this L*a*b* diagram. It is clear that a CMYK+OGV process can simulate many more spot colours using seven inks, and for the majority of spot colours contained within the volume there would never be the need to make a separate spot colour plate.

The small squares generated in this colour gamut by the author are the 1,729 spot colours of the new PANTONE+ Extended Gamut swatch book. A CMYK+OGV and a CMYK gamut are simulated by the larger and smaller volumes in this L*a*b* diagram. It is clear that a CMYK+OGV process can simulate many more spot colours using seven inks, and for the majority of spot colours contained within the volume there would never be the need to make a separate spot colour plate. On sabbatical to research and write the second edition of Wiley’s Understanding Color Management, Ryerson University’s Abhay Sharma provides a synopsis of an emerging model and how to apply it for everyday use.

The Color Conference, held this past December in Phoenix, was an orgy of expanded gamut software, tools and technologies. In sunny Arizona there were solutions for expanded gamut printing from Heidelberg, Esko, Xerox, GMG, CGS and PANTONE. It is now important for commercial printers to understand this new revolution in expanded gamut printing, as more of the industry’s biggest technology providers are developing substantial products in this area.

In general, we have printed for a long time using four process colours – CMYK – and when a customer needed something more colourful we created a separate spot channel plate and ordered ink or requisitioned the ink from the in-house mixing lab. This is the way we have worked for many years in offset and flexography. Digital devices, such as the HP Indigo, are also able to print with extra colour units and Indigo customers throughout North America order their spot colour toner from a lab in Rochester. In this type of usage, the spot colour channels did not expand the overall gamut per se, they just sent some colours to the separate plates or printing units.

Colour paradigm shift

Expanded or extended gamut printing is a paradigm shift in terms of colour and colour gamut. In expanded gamut printing, we move from four-colour printing to seven-colour printing and our base set of process colourants is now seven colour, which can be different for different systems. For example, the new PANTONE+ Extended Gamut swatch book is printed using CMYK plus Orange, Green and Violet (OGV). The Xerox iGen5 has a 5th toner station and can extend the colour gamut with CMYK plus Orange, Green or Blue (OGB). The swatch book is available as a traditional swatch book as well as in software – PANTONE Color Manager – and shows how spot colours would be reproduced in seven colours (CMYK+ OGV).

We can create an ICC colour profile for this extended gamut process and analyze the extent of the expanded gamut using colour management tools. One indicator of the increase in gamut size and volume is to assess how many more spot colours can now be accurately reproduced by mix of the CMYK+OGV ink set. The big advantage is that we can reproduce many more spot colours without using separate spot colour printing! In other words, we do not need to make spot colour plates and order spot colour inks to accurately reproduce many spot colours.

In addition, we have the benefit of just keeping the press running with this expanded colourant set and no press wash-ups. Only the most colourful of spot colours with the most exacting and high-paying client would now warrant traditional spot colour treatment in making a separate plate and ordering a spot colour ink.

In an extended gamut printing process, many more spot colours will now be in gamut of a seven-colour process. An important new requirement is that software tools need to give you an indication of the accuracy with which the process can reproduce any given spot colour. Every colour management vendor at the Phoenix conference was showing new software that enabled users to gauge their seven-colour-process ability.

Proof is in the pudding

The new world of expanded gamut printing also needs to consider proofing. We still may need to create inkjet proofs for the customer. The inkjet proofer must be able to accurately proof the CMYK+OGV press sheet. An inkjet proofer does not need to have exactly the same OGV colourants as a press, but it does need to have the ability to print the increased gamut, so typically the Epson Stylus Pro 7900 has CMYK + OG, while the Epson Stylus Pro 11880 has Vivid Magenta to try and keep up with a CMYK+OGV press. It may be non-intuitive, but there is no requirement for the inkjet proofer to have cartridges that match the units on the press it is trying to simulate. An inkjet proofer can use any inks as long as it can create a sufficient colour gamut to proof the press colours.

There are pressures on commercial printing today to increase colour gamut and reduce costs. Using an expanded gamut set meets both of these requirements. It is more economical to use an expanded gamut ink set rather than wash up of spot colours for individual jobs.

We are likely to see increased use of expanded gamut tools and printing in all areas of commercial offset and flexo package printing. We have already seen installations of digital presses with an expanded gamut toner ability. Based on the tools and technologies coming to market, from all the major companies, expanded gamut printing is here today and growing tomorrow.

Print this page