Features

Digital Finishing

Postpress

Getting into the mix

The era of mixing various techniques to achieve unprecedented results

November 7, 2022 By Treena Hein

Print Panther Direct, Oakville, Ont., won a Gold Lead Award from FSEA for the Extreme Digital Guide III. Photo © Print Panther Direct

Print Panther Direct, Oakville, Ont., won a Gold Lead Award from FSEA for the Extreme Digital Guide III. Photo © Print Panther Direct Expertise in combining newish techniques is the new normal in the print finish sector that’s unfolding right now in Canada and beyond. Of course, new techniques and technologies are periodically introduced to every industry. And, of course, it takes time for expertise with these to grow, but when it does, a permanent shift has occurred.

Whether it’s farming, house construction, print finishing or anything else, the ‘best of the best’ lead the way in becoming adept at not only using new techniques, but also in combining them in new ways to achieve unprecedented results. In print finishing, these techniques include foil, spot UV, metallic inks and much more.

Among the best of the best in Canada at combining finishes and technologies is Print Panther Direct of Oakville, Ont.

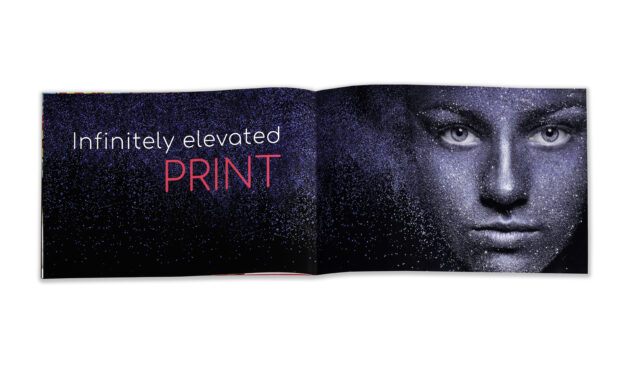

“Having multiple enhancement options at our fingertips allows us to create a masterpiece with every project,” says president and co-owner Christine Yardley. “Combining finishes is the new normal and our Into The Bright brochure is a perfect example of this. It mixes fluorescent pink, metallic inks, white inks, spot varnish and foils to really make images stand out.”

The Into The Bright brochure was printed on the Xerox Irridesse, and embellished on the Konica Minolta MGI Jetvarnish and iFoil. Photos © Print Panther Direct

The expert mixing of finishes is so good in the Into The Bright brochure that it won the ‘Best Use of Digital Foil (Varnish Adhesive)’ category at the 2022 29th Annual Gold Leaf Awards of the U.S.-based Foil & Specialty Effects Association (FSEA).

To produce the brochure, Print Panther Direct printed on the Xerox Irridesse, and embellished on the Konica Minolta MGI Jetvarnish and iFoil. The company has had the first machine for about three years and the latter two machines for about five years.

Yardley and her team have experimented in particular with the fluorescent pink ink and it has opened up an entirely new world of print finish possibilities.

“It can run under everything as a brightener,” she says. “In the brochure, you can see we achieved this wonderful skin tone with a little fluorescent pink under it. You can make this amazing rose gold also by putting fluorescent pink underneath. It’s endless. You can literally make millions of new colours.”

Print Panther Direct printed the Extreme Digital Guide III on a Konica Minolta AccurioJet KM-1e UV LED inkjet press. Photo © Print Panther Direct

More pink, more awards

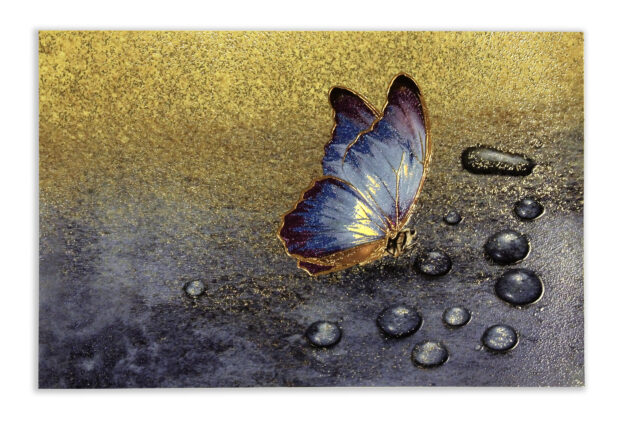

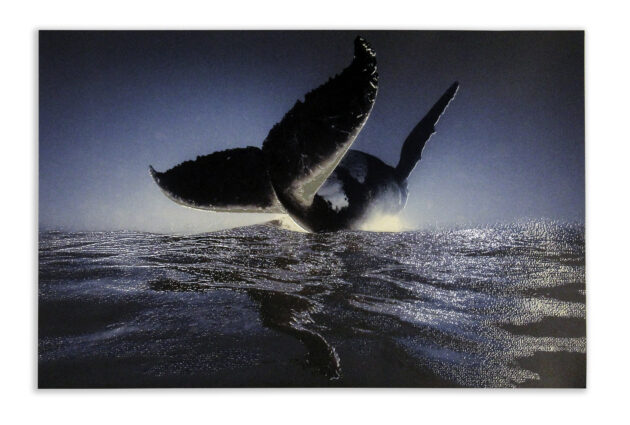

Besides winning for the Inside the Bright brochure, Print Panther Direct also won the Gold Leaf Award’s ‘Best of Show’ for digitally embellished promotion with its Konica Minolta Print So Real You Can Feel It – Extreme Digital III book and box. It’s another example of many techniques and consummate skill in combining them, with textured stock, metallics, gloss foils, holographic foil, spot varnish and fluorescents, especially pink.

The Extreme Digital Guide III was printed on a Konica Minolta AccurioJet KM-1e UV LED inkjet press. The AccurioPress also was used throughout the print process. Metallics and fluorescents were added from the Xerox Iridesse, and the foil and varnish effects were created on the MGI Jetvarnish 3DS and iFoils.

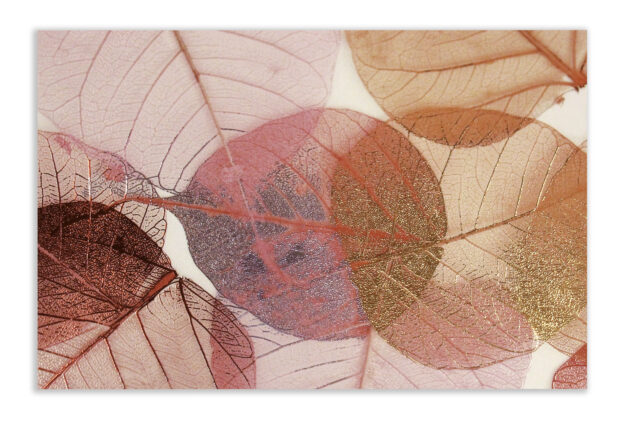

The book images were constructed on 130 lb Cougar “and then duplexed,” as described in FSEA’s PostPress Magazine, “with the visual arts spanning both sides for an endless textured impression…The varnish reflects light and enhances the sharpness and saturation of the images. It gives the primary area of print an incredible look. The impact of the…foil and varnish leaves those who see it with a lasting impression.”

The metallics and fluorescents in this image were added using the Xerox Iridesse. Photo © Print Panther Direct

The outer box is aluminum that was printed and etched, with a belly band of 130 lb Cougar that was “delicately printed, laminated, embellished and scored.”

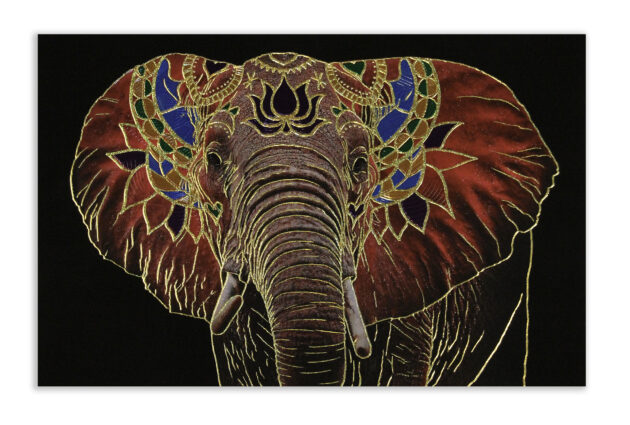

Upon opening the box, a number of striking imageboards are presented, and the picture of the elephant in particular stands out due to the use of fluorescent pink (in combination with lamination, multiple foils, metallics and varnish.

“From the flysheet to the foil on foil and multiple pass techniques, each piece illustrates the sheer beauty that can be achieved,” says Yardley. “Truly a bespoke approach to the printed page.”

This picture of an elephant stands out due to the use of fluorescent pink. Photos © Print Panther Direct

Digital expertise

Among all types of print finishes, digital embellishments have seen the most growth in recent years, notes Jeff Peterson, FSEA executive director. Since no tooling (dies, plates or screens) is involved with digital processes, it obviously provides the opportunity to apply embellishments for shorter runs that can include direct mail, invitations, stationery, labels and containers.

Stephen Longmire, national sales manager at Sydney Stone in Mississauga, Ont., notes the “tremendous increase in short-run boutique packaging and prototyping” that has overtaken the print industry has also been supported by the advent of the flatbed cutting system.

The Into The Bright brochure mixes fluorescent pink, metallic inks, white inks, spot varnish and foils to make images stand out.

Specifically, Peterson explains the growing use of digital embellishment processes “has opened up further opportunities for foil and spot specialty coatings for a variety of applications.” However, at the same time, he says, “Digital embellishment technology has also helped spark growth in more traditional print embellishment methods such as hot foil stamping cold foil, and UV spot screen coating processes.” Peterson says the limitations relating to the addition of specialty finishes, such as metallic foils or spot specialty coatings, have been removed over the last few years, and “the growth in digital foil and coating technologies along with new efficiencies with hot and cold foil processes has provided extended choices for designers and brand owners.”

Indeed, new finishing technologies have fuelled growth in FSEA’s Annual Gold Leaf Awards. This year, there were 39 categories (with a gold, silver, and bronze in each), up from 37 categories in 2021, with the two new categories addressing new technologies for digital as well as conventional methods of print embellishments, finishing and binding.

To help those in print finishing with using the different metallic finishing processes, FSEA has partnered with PaperSpecs to create the ‘Foil Cheat Sheet’ guide. PaperSpecs is a California-based company that offers videos, webinars and more to its members ‘to provide inspiration, insights and access to crucial, hands-on tools and resources to help designers create printed pieces that ‘wow’ their clients.’

Peterson explains the Foil Cheat Sheet “includes decorative samples and the advantages and disadvantages of hot foil stamping, cold foil, digital foil (both polymer-based inkjet and toner-based adhesives) as well as foil board substrates.” The resource also includes guidance on which papers best suit these foiling methods, best options for short print runs and how to create different foil effects in the same print run. Both a pdf and an actual printed/embellished version of the Foil Cheat Sheet can be accessed on the PaperSpecs website or the FSEA website.

Looking forward

Yardley believes multipurpose machines is where the future of print finishing is heading. “I’m sure they are in the works,” she says. “One footprint, one operator.”

Indeed, Longmire reports Duplo is developing a machine that can do spot UV, metallic foiling and corona effect in one shot.

However, Yardley points out that reliability is a rather large concern in all-in-one technology. “If you have only one machine and it’s down, you are stuck,” she says, “but if you have multiple machines and one breaks, you can still get work done. So, there are pros and cons to each situation. I am sure more pros, though. It is an exciting time.”

Yardley also thinks we will see embellished, elevated print become the new expectation in print finishing, going forward. This trend will come into force for the same reason mixing print finishes has now become the norm. “Brands,” she says, “want more to be noticed.”

An edited version of this article originally appeared in the September/October 2022 issue of PrintAction.

Print this page