Installations

News

Goldrich Printpak Adds Esko Kongsberg

February 2, 2016 By PrintAction Staff

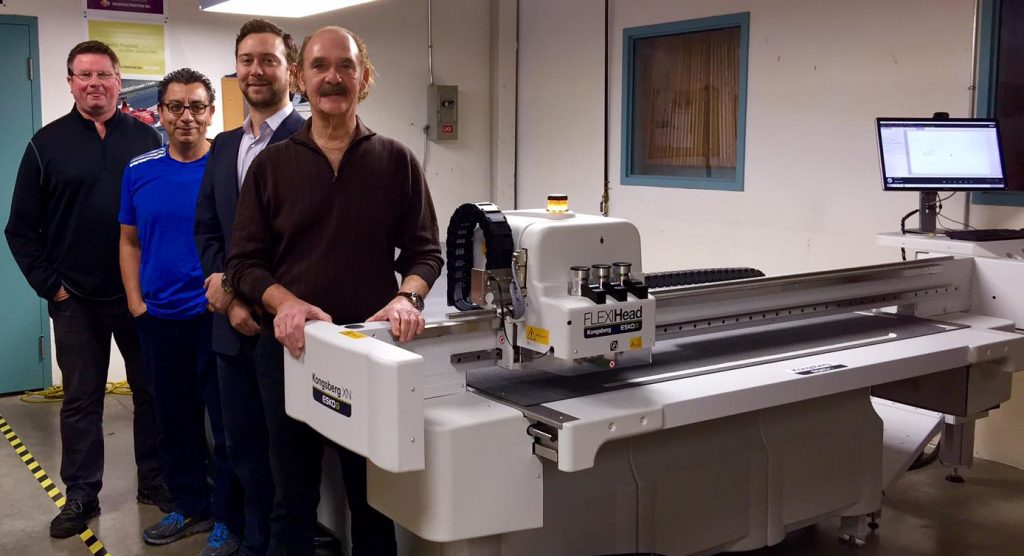

Pictured with the Kongsberg XN 24 are (left to right): Goldrich Printpak’s Simo Molkanen, Litho Supervisor; Marcelo Quinteros, Senior CAD Designer; AJ Goldberg, Vice President, New Business Development; and Leslie Goldberg, President and CEO.

Pictured with the Kongsberg XN 24 are (left to right): Goldrich Printpak’s Simo Molkanen, Litho Supervisor; Marcelo Quinteros, Senior CAD Designer; AJ Goldberg, Vice President, New Business Development; and Leslie Goldberg, President and CEO. Goldrich Printpak, a Toronto company specializing in folding-box manufacturing, has installed an Esko Kongsberg XN24 finishing system and new Esko software into its 67,700-square-foot facility. Both the XN24 finishing table and ArtiosCAD software will be aimed at producing samples and short production runs for its customers.

“One of the services we offer is short-run samples for our customers. A lot of our customers work with retailers who want just one pallet or less of product,” explained Leslie Goldberg, Goldrich President and CEO. “We had an older CAD cutting machine that worked, but had hiccups. It cut samples, but we had to manually make the creases.

“We realized last year that it was on its last legs. We handle cardboard, thin corrugated and plastics and were looking for a machine that could handle these substrates. We wanted a quality machine that could cut materials very well and that was durable enough to work for us for the next 20 years.”

Using the Kongsberg for more than a month now, Goldrich has been leveraging the system particularly for more efficient cutting and creasing of specialized cosmetics boxes, as well as to cut coating blankets for its offset presses, which Goldrich describes as an environmentally progressive way to reduce waste and save costs.

Founded in 1953 as a commercial printer and lithographer, Goldrich Printpak is also focused on continuous improvement in environmentally progressive packaging. The company prints using vegetable based, non-toxic, low VOC and direct contact eco-certified inks.

Before the Kongsberg XN 24, Goldrich explains it would image a plate and then manually cut a sticky back blanket for the press. “The blankets were non-renewable. We’d throw them away. In essence, we would purchase blankets at a cost of $130 to $140 each, plus waste an hour and a half of press time,” said Simo Molkanen, Litho Supervisor and Pressroom Manager. “We are now able to set up standard templates on our Kongsberg table and cut coating blankets that can be reused on our presses. There is both an economic and sustainable benefit for us. We’re in the early stages of preparing these.”

The Kongsberg XN comes with a range of specialty tools and, explains Esko, and the speed, power and flexibility to handle a variety of materials like corrugated, folding carton, solid board, foam, coating blankets, and plastics. The Kongsberg XN 24 can work with materials as large as 1,740 x 3,575mm (68 x 140 inches). The speed of the Kongsberg tables, according to Esko, allows Goldrich to produce short runs of 100 to 300 units.

“One large retail customer recently asked for a full pallet of samples – 160 pieces. Previously it was a nightmare to try to get these projects done. Now, we’re excited to push the table to the limits,” said AJ Goldberg, Vice President, New Business Development. “This morning I’m meeting with a cosmetics customer to deliver 24 box samples made of virgin SBS with a bright silver metallized polyester surface. I do not think we would have been able to get there with our old cutting table. The quality would be much different. Every bad cut would show itself as wavering in the corners and the folds. This is important to us, because it’s our target market – high quality upscale customers where clean folding is important.”

Goldrich is also using Esko ArtiosCAD software to create structural design files to drive the Kongsberg table for both folded cartons as well as the coating blankets. At the same time, they take the artwork file from ArtiosCAD and import it into Adobe Illustrator to add graphics and to send 3D interactive virtual PDF files for clients. They also include the 2D and 3D artwork files with a die line with the factory order as a traveller and quick check of the correct art file, structural shape, and job to be produced. The final job specs are sent from ArtiosCAD to estimating and the company’s software operating system.

Print this page