Headlines

News

Coating

Postpress

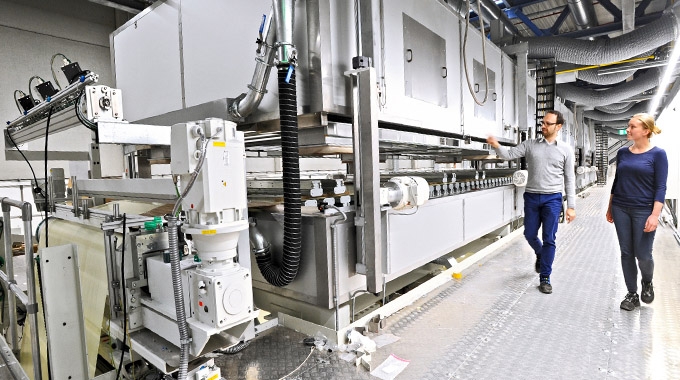

Herma partially opens new coating plant

May 22, 2020 By PrintAction Staff

Herma recently decided to partially open its new coating plant in Filderstadt, Germany for label adhesives, prompted by the implementation of better distancing measures between production teams and an increased degree of automation, reducing human interaction.

The key components of the new plant have been brought into service one step at a time, allowing the company to distribute production orders among its facilities and guarantee its employees better protection.

“In consequence, we are now operating two entirely autonomous plants. In other words, the availability of duplicated systems maintains our ability to fulfil orders, even if production needs to be suspended in one of the plants,” said Sven Schneller, managing director, self-adhesive materials division, Herma.

The remainder of the new plant is expected to open this summer. Once open, Herma says it will increase its annual self-adhesive material capacity by 50 per cent, to 1.2 billion square metres. The technical resources of the new facility will enable producing innovative adhesive materials, including materials for shipping labels. When produced without a liner as Herma does, shipping labels are environmentally-friendly and are produced largely or exclusively from recovered raw materials.

With automated guided vehicles, packing robots and an advanced energy policy, the new plant is among the most efficient of its kind.

“Thanks to a special combined cooling, heat and power plant, Herma can dramatically reduce its primary energy consumption in the new facility. While highly sophisticated from a technical perspective and giving rise to a slightly extended construction period, it enables us to generate up to one-quarter of the electricity that we consume,” added Dr Thomas Baumgärtner, managing director, self-adhesive materials division, Herma. “In addition, we use the heat produced by power generation for heating purposes in the wintertime, and during the summer we use it very efficiently to provide the energy needed for cooling.

Herma is also using, for the first time in the industry, automated guided vehicles to carry rolls of paper, film or coated label stock, which can be up to two metres wide and weigh almost five tonnes each. Herma’s driverless fleet consists of 10 vehicles which, when loaded, are about the size of a large commercial van.

Print this page