Interlinc Direct Corp., based in Mississauga, has purchased a Pitney Bowes FlowMaster RS Flex inserting system to boost its production of personalized marketing materials. Interlinc operates a fulfillment and print facility integrated with its Web-based management information systems to manage, control, track and distribute marketing assets.

Interlinc Direct Corp., based in Mississauga, has purchased a Pitney Bowes FlowMaster RS Flex inserting system to boost its production of personalized marketing materials. Interlinc operates a fulfillment and print facility integrated with its Web-based management information systems to manage, control, track and distribute marketing assets.

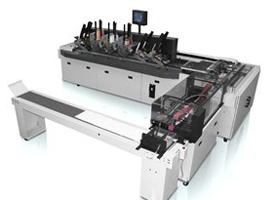

The Pitney Bowes FlowMaster RS Flex inserter can process a range of materials and sizes, including letters at speeds of up to 16,000 pieces per hour and flats at a speed of up to 12,000 per hour. The production speed for flats is described by Pitney Bowes as a 25 percent increase relative to the company’s previous FlowMaster RS generation.

The FlowMaster RS Flex is built around servo-motor technology, which provides for the application flexibility in processing letters and flats on the same platform. With the new system, Interlinc states it is anticipating an increase of inserting efficiencies of around 40 percent.

“It’s essential to be able to customize each and every communication, which is a huge undertaking when conducted manually,” said Neil Raven, Founder of Interlinc. “With our investment in Pitney Bowes’ technology, we can help our clients get an edge on their competition through intelligent, selective inserting where we can be methodical by matching a specific message to a specific person.”

Print this page