Features

Packaging

Koenig & Bauer Durst expands portfolio with new press

May 19, 2022 By Alyssa Dalton

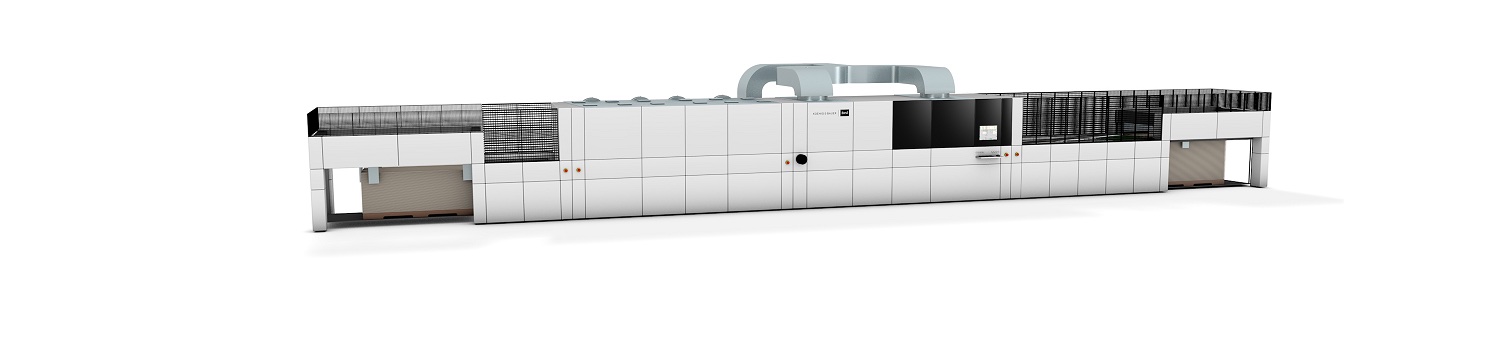

Koenig & Bauer Durst unveils the Delta SPC 130 FlexLine Eco+ industrial production press for run lengths from one to millions of square metres. The entry-level, compact model will offer corrugated converters a new route into digital packaging or will enhance their current capabilities.

The Delta SPC 130 FlexLine Eco+ press can print media sizes of up to 1.3 m x 2.8 m. This new press will be fully upgradeable to the Delta SPC FlexLine Automatic press. The new machine will be addressing converters with volumes of between 4 million and 8 million m2 a year. It also includes a compact drying system.

Koenig & Bauer Durst have introduced the Dynamic Nozzle Management (DNM) tool, which is expected to reduce printhead maintenance across its Delta SPC 130 product portfolio. The tool identifies nozzle clogging and can then be programmed to manage the level of ink being jetted from the head.

Matthias Krautgasser, Koenig & Bauer Durst’s Delta SPC 130 product manager, said, “We have already implemented our automated non-contact cleaning system – DNM will further increase uptime and productivity of our Delta SPC 130 product lineup. DNM is another tool in our parcel of advanced technologies, which will give our customers even more confidence in these challenging times. The DNM will be fitted to all new products, including the Delta SPC 130 FlexLine Eco+ model that will be available from next year. It can also be upgraded to existing customer machines. Many of the corrugated converters we are in discussion with have run lengths of between 4 and 8 million m2 per year, so the new Koenig & Bauer Durst Delta SPC 130 Eco+ will be perfect for them, with the capability to upgrade to the SPC 130 FlexLine Automatic press later.”

Robert Stabler, managing director, Koenig & Bauer Durst, said, “Raw material shortages, cost pressures and mitigation strategies continue to be high on the agenda for customers. Coupled with brand owners demanding that new production methods are reliable, compliant and cost effective, we are confident that our complete product portfolio, including the new Eco+ press from Koenig & Bauer Durst, will meet the rapidly changing requirements. It was clear from discussions at our SPC Open House that converters increasingly need to have the capabilities and competencies to mass customize without any compromise on quality, and all at an effective total cost of ownership, which we provide.”

Print this page