Features

Packaging

Printing

Transcoat to unveil new labelstock technology

October 10, 2018 By PrintAction Staff

At Labelexpo Americas 2018, Transcoat unveiled new technology designed for label printers to make their own laminate while saving time and money.

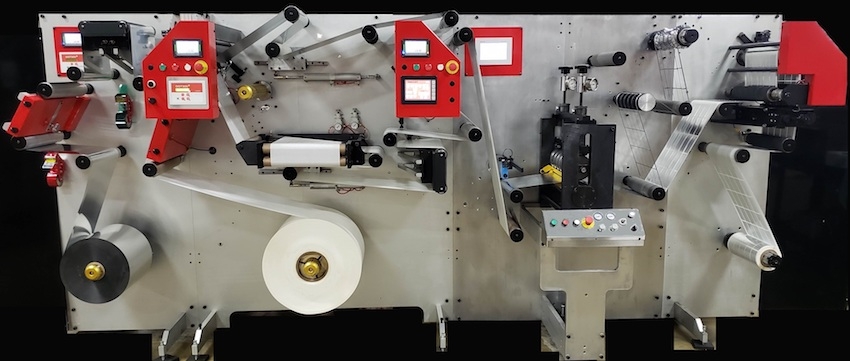

The Transcoat labelstock laminator unwinds faceless rolls (consisting of adhesive and liner only) and laminates any face material (paper, film or other) to generate the final PS construction. Faceless rolls are offered in different width and adhesive technologies (hotmelt, UV Acrylic or emulsion acrylics).

Boasting a very small footprint, the labelstock laminator does not require support from highly skilled operators, quality control chemists or product development specialists, says Transcoat. Additionally, the company says the technology pairs well with a digital press to create unique products by enabling printers to reverse print clear facestocks before lamination as well as double-side print on opaque material. The equipment can be fitted with a flexo, digital printing, die-station and other converting modules, Transcoat explains.

Print this page