Installations

News

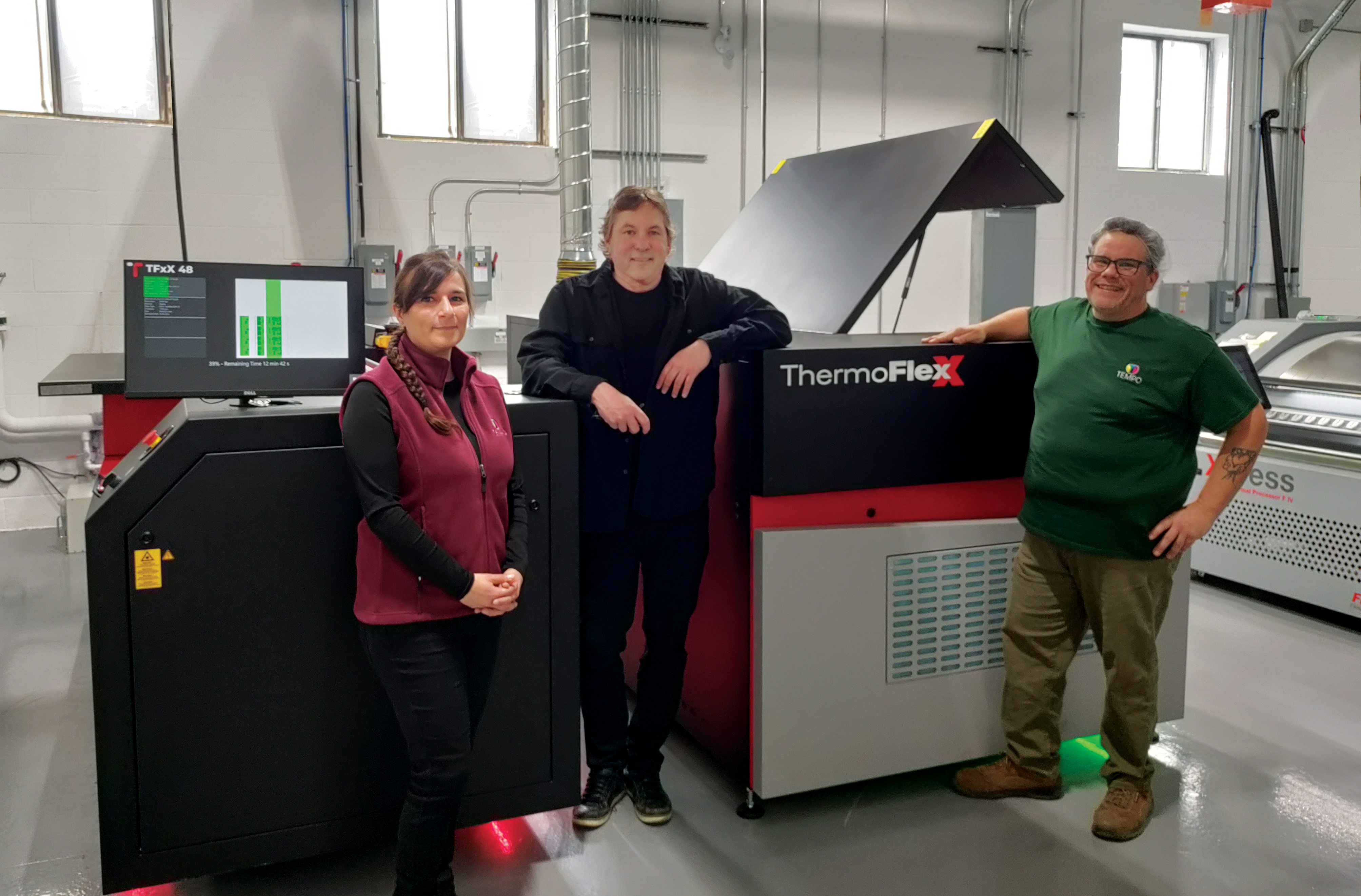

Tempo installs North America’s first ThermoFlexX Catena-E 48

May 5, 2023 By PrintAction Staff

First established in 1970 as a poly bag manufacturer, Tempo Flexible Packaging has spent the past two years implementing a large-scale investment plan. Over 10,000 sf have been added to its facility in Innisfil, Ont., along with the installation of new equipment, including a new CI flexo press from Germany. The ambitious project also involved upgrading the plate room with the new Catena-E 48 exposure unit from XSYS, which was introduced late last summer.

The family-run company is the largest employer in the area with over 170 employees and supplies a wide variety of flexible pouches, as well as roll stock and bags to the food, pet food, and lawn and garden industries across North America. As a vertically integrated manufacturing facility, Tempo is certified to FSSC 22000 v 5.1 standards, with all processes contained within the business, from extrusion, coating, printing, laminating and slitting to final bag- and pouch-making. At the helm sit the children of co-founder Joseph Giglio; Lee-Anne Giglio is the company’s COO, while her brother Leonardo Giglio is the CEO.

Always striving to deliver exceptional packaging solutions for every client, Tempo Flexible Packaging continues to improve every aspect of its flexo printing operation. When it comes to choosing new equipment, the evaluation process is rigorous as technology from different manufacturers is subjected to close scrutiny before the final purchasing decision is made.

Craig Labossier is the print technical services manager at Tempo. He explained, “We had a pre-existing relationship with XSYS since we purchased the ThermoFlexX imager and Xpress processor in 2020, but we still did due diligence to ensure we got the best machine. Ultimately, we were down to two contenders, and it quickly became clear that the Catena-E technology had a strong advantage.”

The Catena-E 48 thermal system can image plates in sizes up to 900 x 1200 mm. It replaced an older conventional bank exposure unit that was causing quality issues for Tempo.

“Even though we are already an award winning printer, we were never really that satisfied with the old unit and had been aiming towards switching to LED exposure for a while, knowing that it would give us the quality push we needed,” said Craig. “With the Catena-E 48, we can hold much smaller minimum dots, and they stay clean throughout the print run, so we can print for longer, which improves productivity and reduces waste. Our customers are also noticing the much cleaner print they’re getting.”

Print this page