Headlines

News

Premedia

Software

Fujifilm to distribute Tilia Labs’ CAD-based imposition technology

August 4, 2020 By PrintAction Staff

Fujifilm North America Graphic Systems Division has teamed up with Tilia Labs, Inc. to sell its CAD-based nesting and imposition technology to complement Fujifilm’s J Press digital printer for short-run packaging and commercial print applications.

Effective immediately, this agreement between Fujifilm and Tilia Labs means Fujifilm now represents Tilia Labs on three continents, making it the company’s largest global distribution partner.

“For our customers, it’s about bringing a unique solution to the challenges presented by short run packaging. To be profitable in this area, manufacturers must find ways to automate the CAD layout and imposition process that is typically very time consuming and manual,” said George Folickman, director of sales for Tilia Labs. “Our combined solution enables these manufacturers to leverage the J Press platform for shorter runs and faster turnaround that otherwise wouldn’t be profitable.”

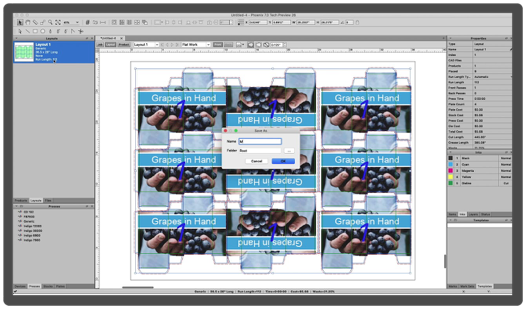

The planning and imposition software, called Tilia Phoenix, uses AI technology to reduce waste and optimize production in all print segments, including packaging, labels, commercial and wide-format printing. Its AI-generated layouts eliminate the need for template-based imposition, and instead adapts to manufacturing requirements and constraints.

Tilia Phoenix offers several features for folding carton and commercial printers, including inventorying die layouts, automatically nesting and populating dies based on quantities and imposing traditional commercial print work.

For digital and conventional printers, the product quickly evaluates the most cost-effective way to run a set of jobs, taking into consideration press costs, ink coverage, make ready, change overs and converting.

Tilia Phoenix can be integrated into Fujifilm XMF or other workflows and MIS systems to deliver faster estimates, reduce prepress time and minimize waste.

The print quality of the J Press 750S surpasses offset, producing detailed images, vignettes, small font text and barcodes. The J Press can print 3,600 sheets per hour, for both static and variable jobs with a maximum sheet size of 23 x 29.5 inches (585mm x 750mm) running both coated and uncoated standard offset stock. The J Press can handle typical folding carton stocks from 8-24 point, as well as offset stocks as thin as 60 lb. text, and output can be easily converted with die cutting, embossing and foiling applications.

Print this page