Features

Data Management

Digital Printing

Packaging

Premedia

Printing

Sustainability

Ready for the digital world?

Variable data management and sustainability are key for digital printing success

May 17, 2021 By Alvise Cavallari

PHOTO © GUMPAPA / ADOBE STOCK

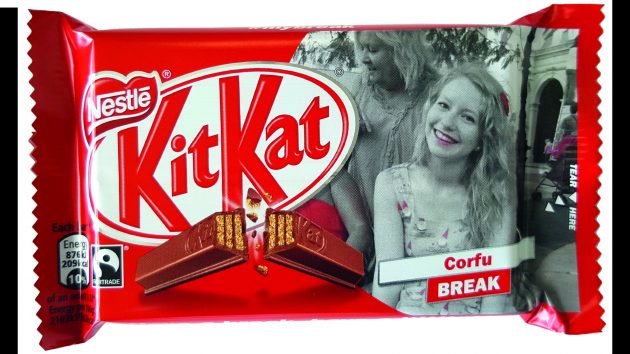

PHOTO © GUMPAPA / ADOBE STOCK The world of packaging is facing many changes. The drivers behind these changes include not only new routes to market (e.g. e-commerce) and multichannel supply chains, but also regulatory and sustainability requirements as well as increased demands for customized and personalized products. Innovative technologies and materials are required for—and indeed enable—these changes to occur. Digital printing is one such breakthrough within the packaging world. It has only taken around 20 years for the centuries-old ‘analogue’ printing industry to reinvent itself ‘digitally’. Digital printing is becoming a reality even in the challenging area of food packaging. The sector was once considered unsuitable for ‘digital’ due to the volume of printing and compliance requirements.

Digital printing is here to stay. The digitalization of printing is a major step toward reshaping the whole converting industry. The main print-press vendors are quite advanced on their digital roadmaps even as new players enter the scene. Though lively, the digital printing industry is fragmented. A phase of business and market consolidation can be expected in the coming years, driven by the need to adapt to new technology needs or uses. We are also witnessing a strong surge in print-in-production, with history seemingly repeating itself, as ‘printing’ comes back to ‘production’.

Each print output is potentially unique with its own variable data that can be managed flexibly by creating an agile printing process.

As our printing journey advances, technologies mature and prices fall, we will always find new opportunities to leverage the benefits of digital printing. However, we will also be confronted by new regulatory requirements and different kinds of barriers. Currently, two factors are critical for the efficient adoption of digital printing.

Sustainability

The first aspect relates to eco-friendly print production. Nestlé has committed to using only recyclable or reusable packaging by 2025. To help meet this commitment, the company established the Nestlé Institute of Packaging Sciences to explore alternative packaging materials along with suppliers and other external partners. We can already anticipate that these materials, such as paper-based laminates, have lighter barrier properties compared with materials in use today. This presents a challenge to the related printing processes that will constrain their use. Of course, digital printing inks have made huge progress in food-compliance and are still improving. However, on new packaging materials with lighter barrier properties, some printing systems (the combination of a printing process, an ink and its finishing process) must be adapted to meet strict food packaging requirements. Additional goals, such as reusability and recyclability, should also be considered. Are today’s ink formulations, developments and finishing processes ready for this transition?

The first aspect relates to eco-friendly print production. Nestlé has committed to using only recyclable or reusable packaging by 2025. To help meet this commitment, the company established the Nestlé Institute of Packaging Sciences to explore alternative packaging materials along with suppliers and other external partners. We can already anticipate that these materials, such as paper-based laminates, have lighter barrier properties compared with materials in use today. This presents a challenge to the related printing processes that will constrain their use. Of course, digital printing inks have made huge progress in food-compliance and are still improving. However, on new packaging materials with lighter barrier properties, some printing systems (the combination of a printing process, an ink and its finishing process) must be adapted to meet strict food packaging requirements. Additional goals, such as reusability and recyclability, should also be considered. Are today’s ink formulations, developments and finishing processes ready for this transition?

Data management

The second aspect underlying the promise of digital printing has to do with variability in the printout (output) as well as flexibility in the printing (process). Print jobs are increasingly related to data management, as each output is potentially unique with its own variable data that is managed flexibly within an agile printing process.

Late-stage customization is the ability to customize the output at the latest stage, which itself refers to moving printed packaging from a conventional rigid supply-chain to a networked supply-chain where multiple players can print different static and variable layers of an artwork in one or several locations. It means moving away from a monolithic approach where the full printing and converting processes are entirely outsourced to a situation where many supply-chain options are available to cover the high variety of products, business models and routes to market (from fully outsourced supply to fully internalized printing and converting, with mixed approaches in-between). This is our definition of variability and flexibility, derived from data-driven print production and late-stage customization.

To achieve all this, the dots need to be connected, meaning the print-job data as well as the printing and converting process must connect seamlessly into an integrated end-to-end supply-chain workflow. This integration and connectivity happen in two dimensions, namely horizontally and vertically. Horizontal integration involves the progressive digitalization of the complete converting machinery and processes, streamlining the repro while ensuring colour matching and consistency. This digitalization has already occurred for the artwork and prepress; is happening for the printing step; and will progressively include the decorating, cutting and folding-gluing steps as well as other converting steps. Vertical integration relates to the print and converting-data. It ensures the right output is achieved from the correct data in a make-to-order or print-to-order model. Both static as well as variable artwork data must be aggregated dynamically together with production-specific data coming from a production order, which, in the end, can make every pack literally unique, if required.

At first glance, this degree of integration and connectivity to achieve a batch-of-one might sound futuristic, and is definitely ambitious, but the reality is that all the necessary technology-related building-blocks already exist. Digital front-ends rip dynamic artwork for the printer. Manufacturing execution systems dispatch production order information to the various assets of a production line. Dedicated servers ensure additional functionality, such as serialization or aggregation. For each and every type of data, a dedicated and well-optimized channel exists. Additionally, connectivity standards are maturing and being adopted to ensure both horizontal and vertical communication between all the modules of a production environment. All these channels, which are mainly independent today, can start to be interconnected to combine, as and when needed, the relative data, rip it accordingly, and finally print it to produce unique packaging items.

Data is the fuel of today’s economies. The ability to create, collect, handle, combine, extract, analyze, process and convey data will drive the most efficient businesses. Printing is no longer about accurate colour-matching and process-efficiency. It is rather about conveying to buyers and consumers digital information that has been applied physically on the pack. Some call it the blended reality. Nonetheless, it is a paradigm shift enabled by combining digital printing with connectivity. Such a shift is a prerequisite for achieving personalization and customization, the “holy grail” of the digital transformation in consumer package goods (CPG). This paradigm shift can help one envision the connected production-floors and factories of the future.

Alvise Cavallari heads Nestlé’s corporate digital printing programme as well as other related activities.

This article was originally published as part of the Drupa Essentials of Print series and reproduced in the April 2021 issue of PrintAction.

Print this page