Features

Premedia

Software

Xitron introduces Navigator Flexo Suite

September 28, 2018 By PrintAction Staff

Xitron, a developer of RIP and workflow products for commercial, digital, flexo, and high-speed inkjet printing, has introduced Navigator Flexo Suite at Labelexpo Americas 2018. Comprised of several productivity tools designed specifically for flexo imaging, the modular workflow is described as being fully compatible with any flexo CTP engine that accepts one-bit TIFF files, such as Amsky, Cron, and Xeikon.

Conceptualized in meetings with several flexo CTP vendors at last year’s Labelexpo in Brussels, the package was developed, tested, and sent to beta accounts around the world in the span of nine months. “We had a very specific list of requirements with which to work,” said Karen Crews, President of Xitron. “Besides our meetings with Flexo CTP manufacturers, we also worked with distributors and dealers before building the product roadmap. This gave us a short list of ‘must-have’s’ in terms of functionality. All of our CTP partners wanted a competitive price point, productivity beyond existing systems on the market, and the option of high fidelity screening for applications that require it.”

Navigator Flexo Suite starts with the Navigator RIP platform, of which more than 35,000 have been sold in commercial, in-plant, digital, screen printing, inkjet, and flexo markets around the world.

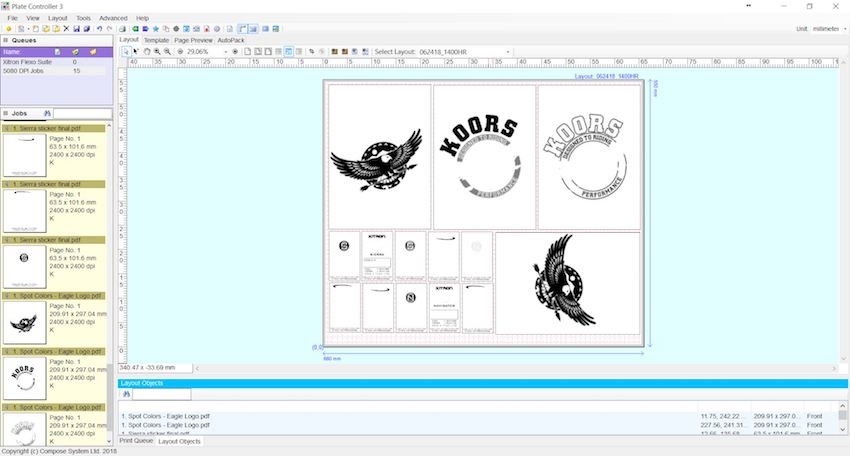

It’s coupled with the Client-Server properties of the Navigator workflow, which gives prepress operators and artists independent submission, modification, pixel-level preview, and throughput control of jobs from their own workstations. This allows them to work independently and without interruption from anywhere on the network, says Xitron. Finally, all the colour separated job plates are collected by Navigator Plate Controller, which helps the operator assemble the final flexo plate for output with as little material waste as possible.

The optional high-fidelity screening engine gives users the ability to specify FM to AM crossover points between highlights/shadows and mid-tones while also letting them determine minimum dot size through nine levels of sustainable “smart dots.” Users are able to customize the screening based on platesetter exposure accuracy and the print results of each individual press. Those customized setups are retained as screening templates for repeated use.

Print this page