Features

Chronicle

Opinion

Cutting to the chase

You can only print what you can fit in a (press) chase

August 29, 2018 By Nick Howard

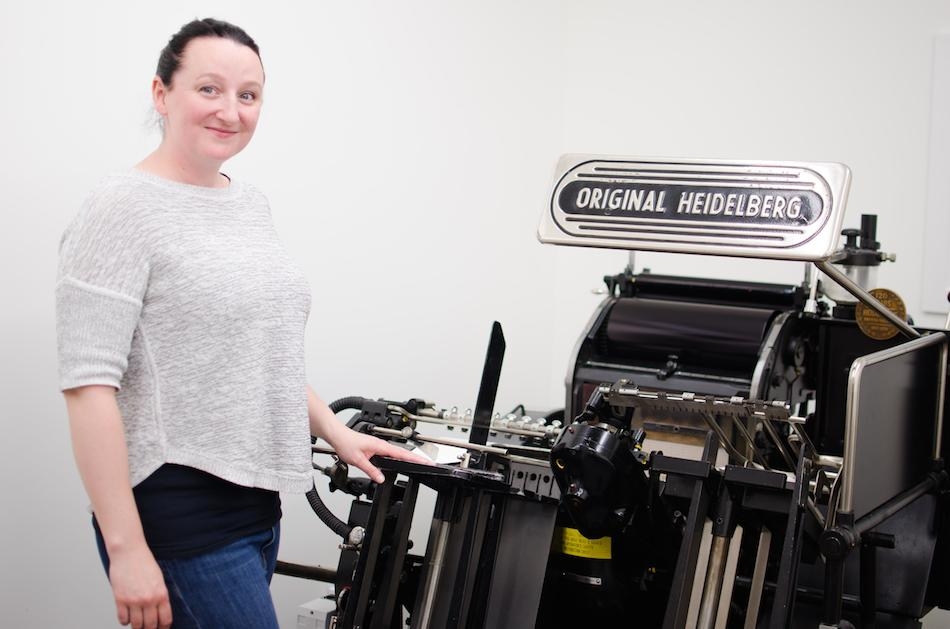

Sybille in her workshop setting up and running her new Heidelberg T platen.

Sybille in her workshop setting up and running her new Heidelberg T platen. Tactile – representing exciting new processes brought by early pioneers Scodix and Konica-Minolta/MGI, showcase how we have moved from “essential print” to eye-catching communication. As more of this digital technology enters shop floors, one thing is clear: The hardware is pricey.

Whether with thick specialized varnishes that pop off the page, or hot and cold foils that mimic more traditional techniques, these eye-candy effects dazzle without the same skills needed for relief printing (letterpress). Printers can now do more exciting projects in-house. But can they sell enough of these new effects?

We all get how the traditional print model has transformed in the last 15 years and a good portion have made substantial efforts to be part of the next digital wave. The winners have figured out why their clients will pay twice as much for a coffee. Sadly though, industry news is often dismal. Seems almost daily, word spreads of another shuttered plant or a reduction in print periodicals. The once dependable forms and stationary sector has been essentially wiped out by online paperless solutions. Just last week our HVAC tech was onsite for a service call. When completed he handed the office manager a tablet and asked for a signature. He wasn’t even out of our parking lot when into our inbox whizzed an email invoice.

Anyone successful today already bade farewell to all the loser segments. But there is a new group – for the first time in a long time – entering our industry.

On a recent afternoon, we had a visitor, excited and full of enthusiasm. With husband in tow, Sibylle was here to learn how to run her new Heidelberg platen. Wow, is Sibylle passionate about print! Just a few years ago, working out of the family garage, Sibylle started off with a 10 x 15 inch hand-fed platen. Soon her creativity in designing and printing all types of stationary and wedding invitations forced her to look for a better and faster press than the old Chandler & Price. Busier than ever and with more demanding designs requiring multiple press passes meant getting an automatic letterpress was a necessity.

I’ve never seen anyone learn the Heidelberg as fast as Sibylle. After two hours of instruction she was off to the races.

Why? Sibylle and all the letterpress lovers who come to our museum simply fall in love with the letterpress process and want to learn. It may also help that just like Sibylle, most are university educated, have worked in disparate industries and are drawn – like a magnet – to the enjoyment of letterpress’s version 2018.

Similar things happened with a couple in Miami who flew up to buy their windmill, a young lady in western Canada who had her heart set on a hand-fed platen, the card shop owner in Moscow who simply had to have a Gordon. Then there is the truffle maker who insisted on doing his own label diecutting and the boutique chocolatier who wanted to print and diecut his own boxes. Maybe the most enthusiastic was the gentleman who drove right across the country to load up an R.HOE hand iron press. Letterpress isn’t just localized either. Besides Russia we’ve sold presses and Columbians to universities and museums in Boston, Ann Arbor and New Zealand. These are just a few of the thriving folks entering the world of printing and loving it.

When we have visitors at the museum they often get very excited with the array of type and machines. Women especially bring a zeitgeist into the space our industry hasn’t seen for a long time. This male-dominated industry needs more women like Sibylle who break the taboos.

As depressing as world news can be, folks living in developed countries are generally doing better than ever. They seem to have more personal time and more money to enjoy the things they really want to do. Print, as well as other forms of ink on substrate communication, is still a creative process. Someone has to manipulate type and images to make a bespoke article that besides being exclusive is also made by hand. Take a look at fashion. Virtually all of it comes from mass production using machinery. But high fashion Couture clothing is handmade.

Monster offset sheetfed sales are shrinking because they are very good at only one thing – analogue mass production. Unless this exists (packaging, labels etc.) the graph chart looks like the backside of a letter “M.” But as I can clearly see, now is the cool rebirth of print. Only this time from a long ago technology that was made redundant by the offset press: Letterpress.

For less than $15,000, you could easily equip a small print shop. Even if as most do, farm out their photopolymer printing plates, all you need is paper stock, ink, a manual platen press, small guillotine and a thirst to be the operator. No one even needs to use the original lead type anymore as photopolymer plates are excellent and eliminate all the “locking up the form” challenges.

If you succeed in doing reasonable quality then get a Shopify or Etsy platform and start soliciting business. The small cottage industry letterpress shops can market their products the same way large printers do with the Internet. The ability to showcase your designs and abilities, take orders and receive payments is a major ingredient to success.

What we call “Letterpress Printing” today would have got you fired back in the 1950s. The heavy embossing into paper is what clients look for. I quit telling our new friends why they aren’t respecting the original craft as they simply don’t care to know.

Here’s to Sibylle and the exuberant new generation of printers that have a real passion for the art of printing. All measured by the growing public that seeks to differentiate themselves when they too want to use print. Small perhaps but Sybille and her fellow artists are helping the rest of the industry promote itself. You have to really love what you do.

This column was originally published in the July/August 2018 issue of PrintAction, now available online.

Print this page